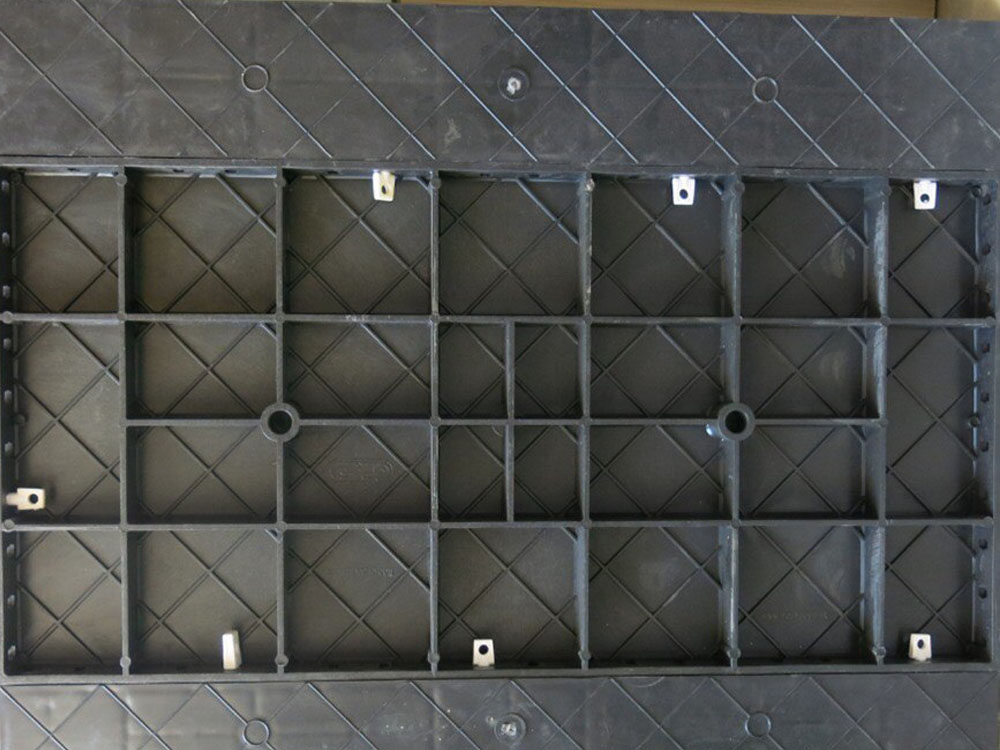

polyform modular formwork is made from composite material based on a polymer matrix; the formwork is formed by heating the material up to 400 c and injecting it into high precision mold. the result is a product that is lightweight, strong, and highly precise; with a working temperature from -20c to 130c.

polyform modular formwork is a system with up to 5 components. it can be applicable for up to 90% of construction projects. it is another product parallel to wood formwork that can be used in a single building from top to bottom.

with unbeatable price, less weight, faster execution, and minimum training, resulting in high-cost effectiveness, that makes polyform mold extremely ideal for all construction projects worldwide. polyform works well under all weather conditions.

The price of polyform molds is undeniably lower than metal and aluminum molds. and compared to wooden and plywood molds, due to the number of times of use, it is much less.od molds, due to the number of times of use, it is much less.

Polyform modular formwork can be easily assembled by local labor with short-term training. No high-salary professional workers are needed. for more accurate execution and control, a complete layout plan based on the shape of the building plan is available.

Versatility is the key advantage of polyform molds, which have different components applicable for all types of construction projects, especially for non-standard designed projects. these molds are easily cut and it is possible to make different shapes with them.

The presence of special grooves on the mold makes plastering the concrete surface extremely easy and inexpensive. it also prevents the spread of micro cracks on the concrete surface.

Polyform molds are extremely durable and waterproof. it can be used under any weather conditions, is easy to transport, and can be stored in an outdoor environment.

There is a possibility of recycling and return of investment up to 25 % and replacing depreciated molds with new ones easily.

It is possible to connect to all metal and aluminum modular sections in special and asymmetrical sections and surfaces with polyform molds

The concrete does not stick to the plastic mold and the mold can be easily removed from the concrete surface.

Polyform molds is designed to work with different kinds of frameworks and scaffolding accessories, which allow better site management with less working components.

The weight of the largest polyform mold is only 5 Kg, which makes it easy for workers to carry the molds and the execution speed increases a lot.

Introducing pey Azad Company Pey Azad Manufacturing Company, relying on its knowledge and 40-year history of Pey Azad Construction Company , entered the field of innovation and production in the field of implementing all kinds of reinforced concrete structures to improve the technology level of concrete structures and improve the operational and economic problems of concrete buildings. The first successful product of this series was the durable polyboot ceiling mold (modified Uboot), which has played a perfect and important role in the implementation of hollow ceilings in Iran country in recent years. Another unique product of this set of modular plastic molds is Polyform, which has made a tremendous change in speeding up the implementation of object structures and reducing implementation costs in the construction industry. For the first time in Iran country, this group has obtained industrial ownership of plastic molds in the construction industry from the intellectual property center of the country's property and document registration organization.